The use of immobilized enzymes in industrial processes as chemical reactions accelerators

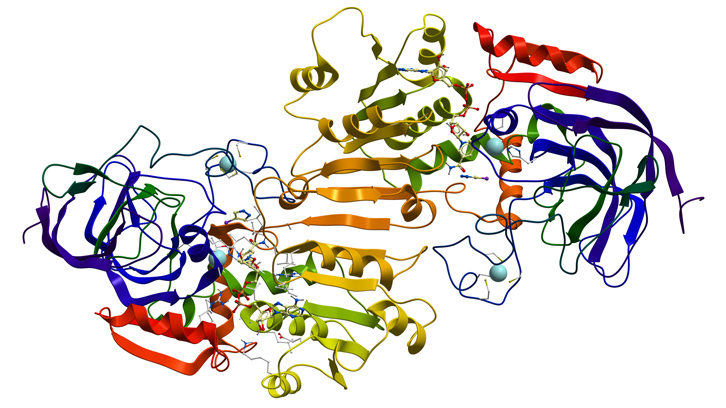

Enzymes are proteins, often combined with other molecules such as sugars, which are present in every living organism. They are responsible for the acceleration and regulation of the chemical reactions essential for life. Enzymes are also known as biocatalysts.

In the industrial branch of biotechnology, the so-called white biotechnology, enzymes are produced in large-scale and then, used as accelerators in reactions with commercial interest. The use of these biocatalysts confers some advantages over the traditional chemistry routes: they are selective for one reaction type, they are generally specifics for one substrate (molecule to be converted), they perform in mild conditions regarding pressure and temperature; and the harsh chemicals used and/or generated are highly reduced. In terms of enzyme production, they are synthesized by genetically modified bacteria, fungus or animal cells; the host organisms. Once the throughput of these “cell factories” has proven efficient, enzymes are applied in the transformation of several kinds of chemical products: pharmaceutical ingredients, nutritional supplements, food & beverage processing, fragrances, etc.

The host organism, can be used straight ahead in the process as a whole cell. However, the substrate/product needs to go in and out of the cell, travelling through the membrane, which usually results in an added ballast. On the other hand, enzymes can also be used as free proteins dissolved in an aqueous solution. In this case though, by placing the enzyme in a different non-native environment, it usually gets deactivated faster. A third option also exists. The attachment of enzymes onto solid particles (the immobilization) confers an extra rigidity and stability to the three-dimensional structure of the protein, which is essential for its activity. Furthermore, it allows an easy separation of the biocatalyst from the rest of the reaction. The combination of both attributes facilitates the reutilization of the catalyst in various reaction cycles. By doing this, the amount of product synthesized with a certain amount of enzyme (the biocatalyst yield), is significantly increased and hence the process metrics improve.

In the Bioprocess Engineering and Applied Biocatalysis Group, enrolled in the European project ROBOX, we are focused on the immobilization and application of a specific sort of enzymes, the oxidoreductases. These enzymes are involved in electron exchange reactions. Among oxidoreductases, in collaboration with University of Maastricht, two of them could be immobilized and further applied in reaction cycles: the CycloHexanone Monooxygenase (EC 1.14.13.22) and the Glucose Dehydrogenase (EC 1.1.1.47). Both, key enzymes in the production of trimethyl-ε-caprolactone, a precursor of the novel polymer poly-trimethyl-ε-caprolactone. This polymer is used, for example, as an ink additive to improve dispersion and homogeneity on the applied surface. In our case, by immobilizing both enzymes, 50-fold more product could be synthesized with the same amount of catalyst.

Figure 1. Bio-reactor and equipment used in the biocatalysed transformations. On the left image, top view of the reactor, there are: the stirrer, the pH probe, the condenser and the substrate, NaOH (pH control) and air inlets. In the central image, front view of the whole set up, there are: the jacketed bio-reactor (top part of the image), the substrate dosing pump (bottom part of the image) and the pH controller (apparatus on the middle of the image). The picture on the left is the front view of the bio-reactor with the previously described components.

Department of Chemical, Biological and Environmental Engineering

Universitat Autònoma de Barcelona

References

The research for this work has received funding from the European Union (EU) project ROBOX (grant agreement n° 635734) under EU’s Horizon 2020 Programme Research and Innovation actions H2020-LEIT BIO-2014-1.