pHotoYOGURT aims at pilot plant level validation of a disruptive optical method, able to determine, inline and non-destructively, the pH in yogurt production tanks. This technology, if successfully validated, would represent a paradigm shift in yogurt manufacturing.

For food safety reasons, the yogurt production industry is legally required to reach a pH of 4.6 to stop fermentation and begin cooling of the product. The traditional system requires yogurt sampling every 10-15 minutes for external pH measurement (off-line or at-line), which generates unnecessary personnel costs and health risks. pHotoYOGURT technology is a non-destructive optical monitoring method that constantly measures the pH of yogurt in real time. It consists of a fiber optic sensor compatible with a clean in situ (CIP), easy to use, installed directly on the wall of the fermentation tank.

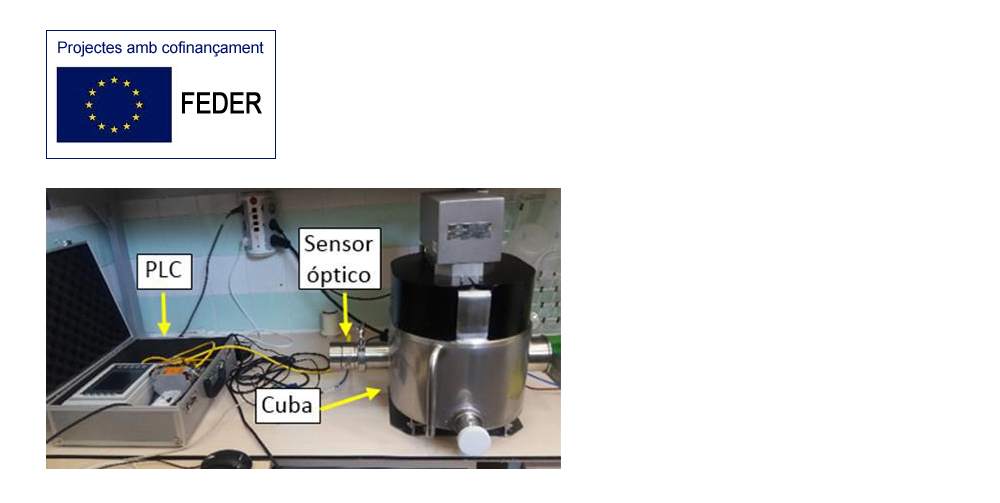

More specifically, the system consists of a small-sized NIR optical sensor that is installed on the wall of a fermenter. An LED emits light that is transmitted by an optical fiber to the milk. The light scattered by the casein aggregates during fermentation is transmitted through another optical fiber adjacent to a silicon photodetector that transforms it into a voltage. The light scattering ratio is correlated with the pH values using a specific algorithm. The data acquisition system consists of a programmable logic controller (PLC) in which the software for data acquisition and fermentation endpoint prediction is installed.

The scattered light contains information about the fermentation that allows the pH to be determined from the scattered light. The pHotoYOGURT technology, which has been developed and patented by the UAB, is the only method available today to transform in real time a non-destructive optical signal into continuous pH readings, which avoid human intervention in sampling of the product, as well as the health and quality risks associated with this sampling.

The implementation of the pHotoYOGURT technology means advantages such as:

- Using a smart sensor like process analysis technology (PAT) in combination with chemometrics as an innovative process to ensure quality.

- Automatic selection of the fermentation end point without human intervention, in line with Industry 4.0 trends (full automation, big data and the Internet of Things).

- Removal of a critical control point in the yogurt production line, in order to avoid possible microbiological contamination, which could lead to quality alterations or health risks.

- Improve batch-to-batch consistency of the final product.

- Reduce syneresis (extraction of curd), a well-known defect in yogurt, which will increase the acceptability of the final product to the consumer.

- Decrease the chances of rejecting batches of yogurt that are below the quality standard, reducing effluents and environmental impact.

- Minimize energy use and associated CO2 emissions by facilitating the optimization of fermentation endpoint selection, contributing to the fight against global warming.

The lack of reliable technology for online monitoring of yogurt pH is preventing the automation of fermentation endpoint selection. Successful pilot plant validation of the pHotoYOGURT technology would complete the transfer of a unique technology capable of continuously monitoring yogurt pH without manual sampling, which would undoubtedly have a major impact at the industrial level.

This project has been co-financed by the European Union through the European Regional Development Fund (FEDER).